Alu. Steel. All you need.

- Schüco FWS50 curtain wall

- Schüco AWS 57 RO skylights

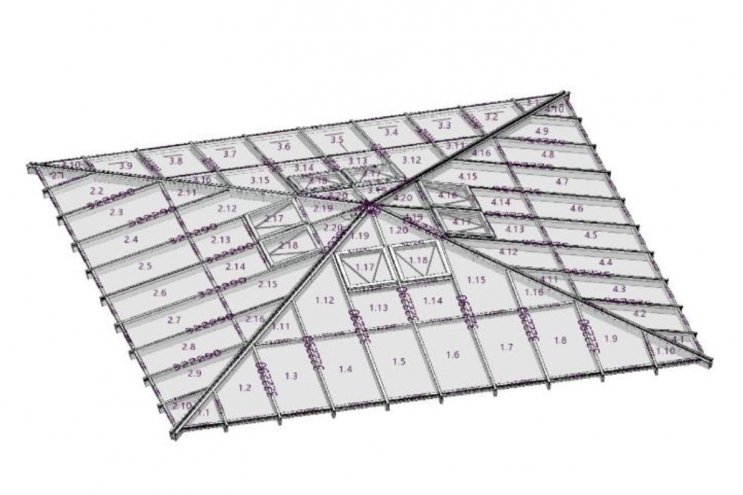

The task was to replace an existing but damaged pyramid structure. The damaged aluminium and glass elements of the existing steel structure had to be dismantled and the new aluminium pyramid structure had to be built, keeping the remaining steel beams and working on a scaffold all the time. The complexity of the work was increased by the fact that, during the site survey, it was discovered that one side of the theoretically 10x10 metre pyramid was 60 centimetres different from the other sides.

Due to the complexity of the task, we used a state-of-the-art laser scanning technique to digitise the site in a model format. This made our work much easier.

We also installed eight heat and smoke ventilation windows to meet the client's requirements. We used triple-layer thermal multifunctional safety glazing throughout the structure.